When the Paris Air Show 2025 opens its doors for the 55th time from 16 to 22 June 2025, it will bring together all the major manufacturers and suppliers to the aviation industry, as well as aircraft operators and airlines. The Nürtingen-based HELLER Group, renowned for its innovative manufacturing solutions, will also be taking part. Under the banner ‘Excellence4Aerospace’, the company will be showcasing its expertise in the highly productive and flexible manufacture of complex components in hall 2b, stand F 194.

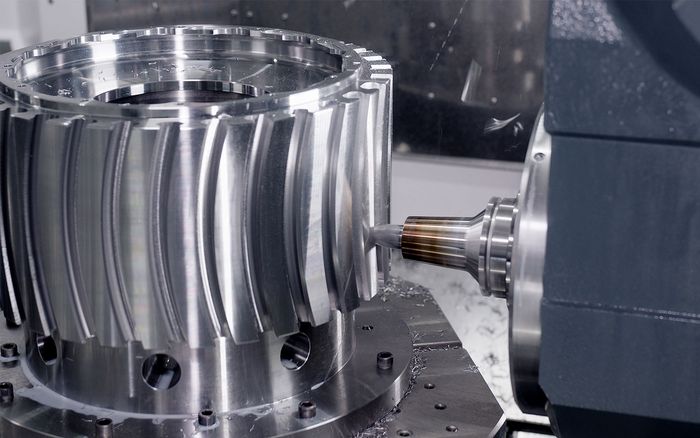

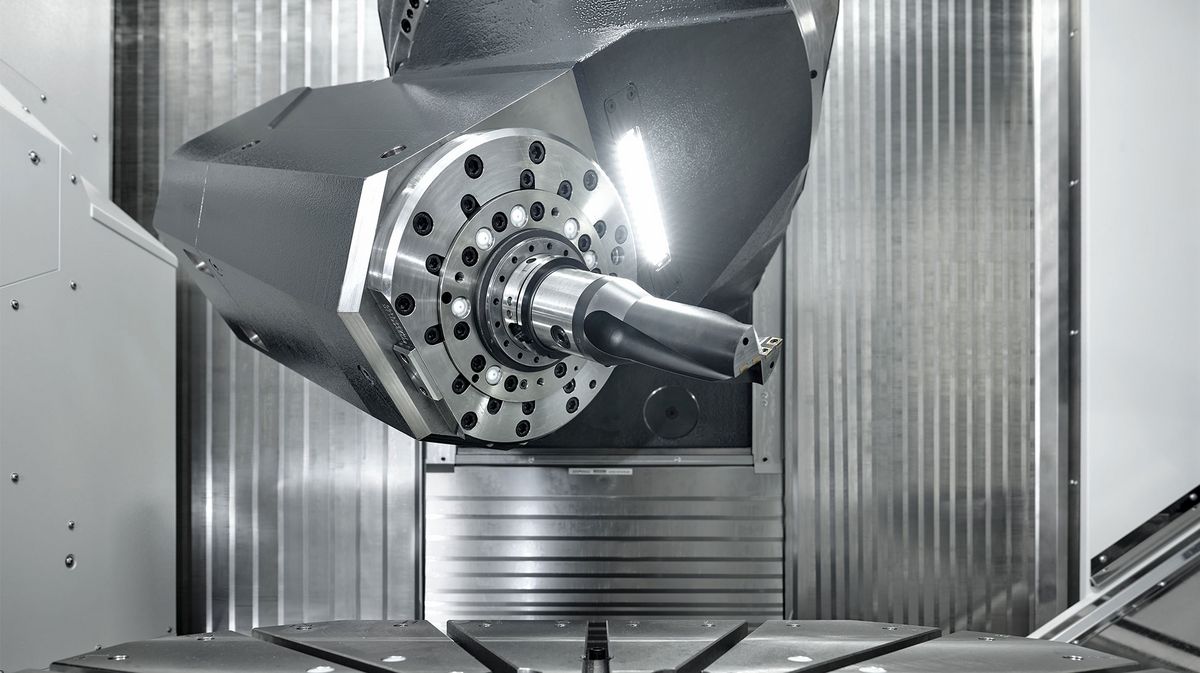

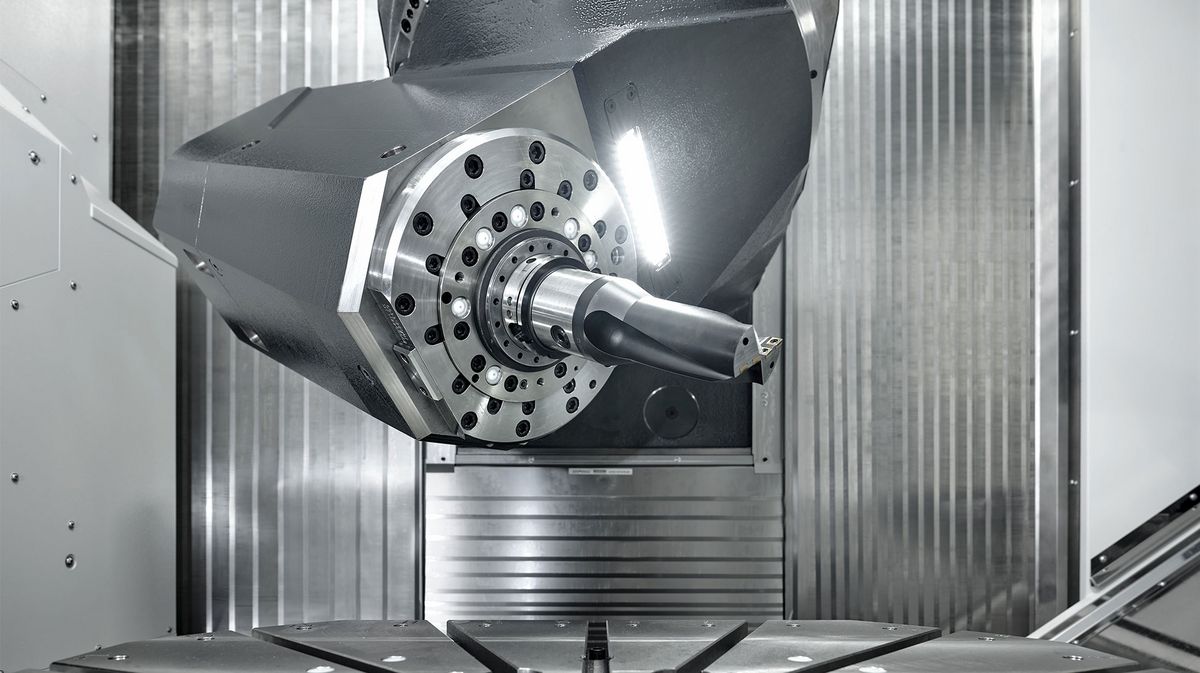

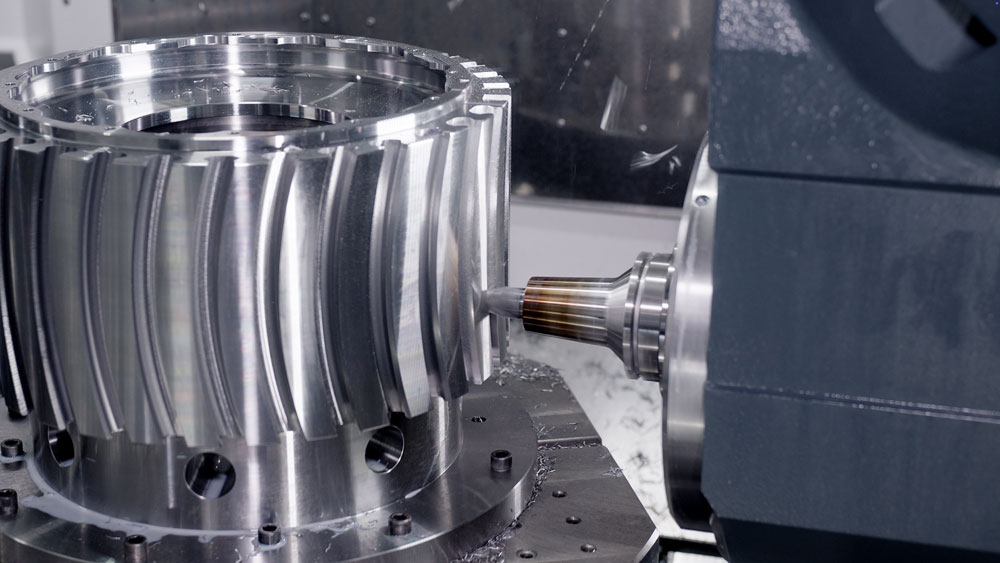

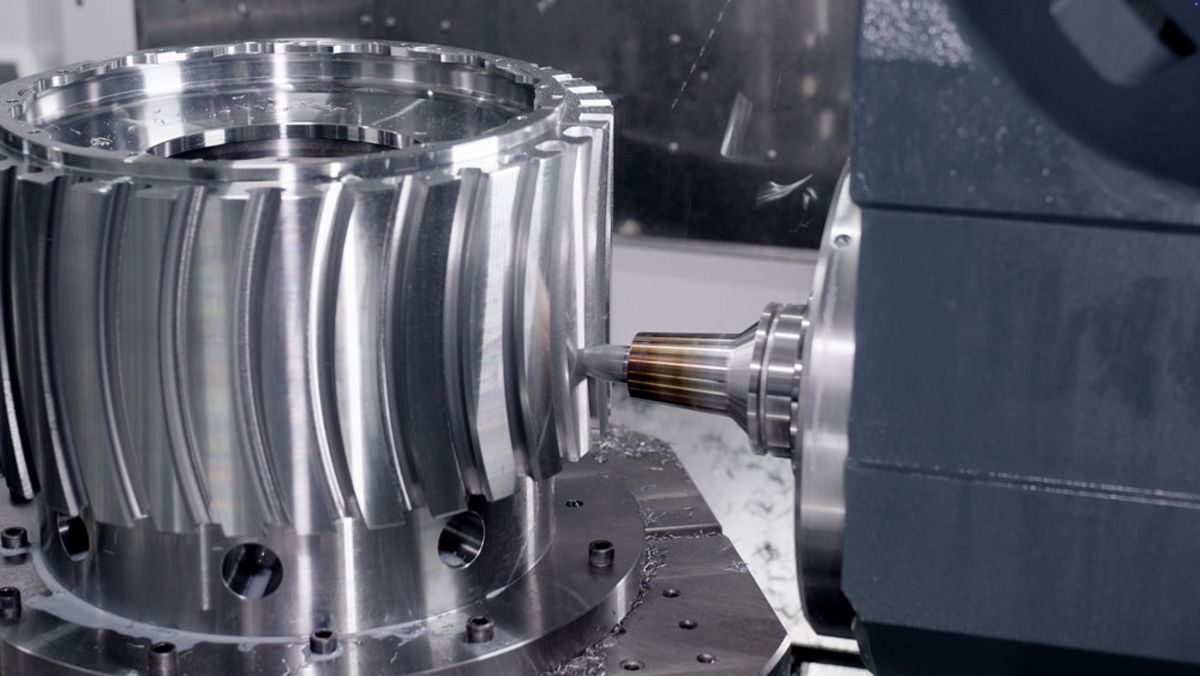

In particular, the 5-axis F and HF series machines have demonstrated their strengths in the production of various sized engine components, doors, chassis and structural components. Especially with regard to the machining of difficult-to-machine materials, HELLER robust and reliable solutions can bring a complete piece of mind to their users, with a strong stability in the processes, rigidity and services. The compact machining centres can also be configured to produce hydraulic components and small mechanical parts. Equipped with a host of advanced features and a wide choice of automation options, all machines are equally suited for single-part manufacturing or flexible 24/7 high-volume production.

Since the end of 2023, HELLER has been launching 5-axis centres from the new F series in various sizes as part of an innovation drive. In addition to their small footprint, the generally high axis accelerations in X/Y/Z of up to 7 m/s2 and position tolerances in X/Y/Z of up to 6 µm have contributed to the increasing demand for these machines. Another advantage is the large work area relative to the external dimensions. As a result, the new Heller machining centres offer a particularly high degree of application flexibility.

With complete machining playing an increasingly important role in many aerospace manufacturing companies, HELLER has embraced this all-in-one concept and offers an optional mill-turn function for combined milling and turning tasks on the F series up to size 10000. This is made possible by the high-torque DDT (Direct Drive Turning) rotary table offering speeds of up to 700 rpm. In addition to milling and drilling operations, it allows to remove stock at external and internal contours in longitudinal or transverse direction in a single set-up, or to produce a wide range of undercuts and recesses. Even cutting of external and internal threads is possible. This eliminates the need for reclamping on separate turning machines, resulting in improved part accuracy and reduced cycle times.

The high reliability of the F series and a range of error prevention features make this advanced 5-axis machining centre even more attractive. The ‘digital twin’ integrated into the Sinumerik One control system enables high-precision virtual mapping of the production process even before the first chips are removed. Then, of course, the dynamic yet rigid HELLER machines run the NC program with the highest precision.

For all those who do not yet know which workpieces and quantities they will be producing in the future, Heller offers the ‘Automation-READY’ option for maximum flexibility. It ensures that the available standardised automation systems can be added quickly and easily at a later date. The F series is always equipped with an automatic pallet changer (APC) as standard. Alternatively, advanced automation solutions are available with linear or rotary storage systems (RSP) or robots.

Further machining centres in the 5-axis HF and 4-axis H series complete the range of flexible and highly productive machines for the production of aerospace components. More detailed information will be available at the Paris Air Show 2025. So, a visit to HELLER’s stand F 194 in hall 2b is guaranteed to be well worth while.